Your cart is currently empty!

This is the story of why Attractec developed ALMAKIT.

We started using liquid metal in 2015,

when nothing else worked

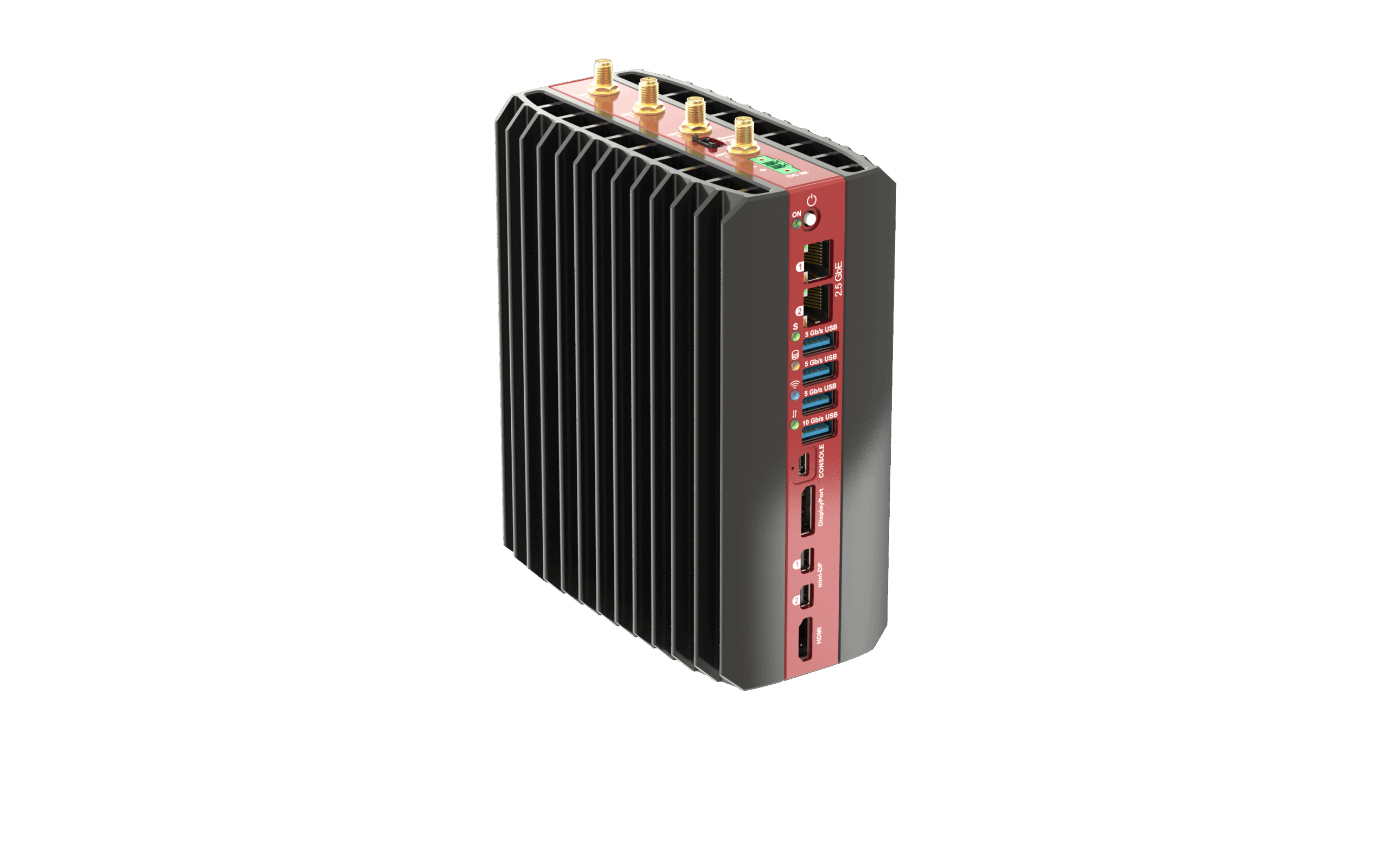

Back in 2015 we were designing a compact fanless industrial PC with the most powerful desktop CPU available at the time, and the CPU was overheating while the heatsink was cool. We tried the best thermal pastes on the market, PCMs and exotic thermal pads. We mirror polished the heatsink to aerospace surface quality and flatness and tried applying mounting pressure well beyond maunfacturer’s recommendation. Nothing worked.

Eventually we tried liquid metal, which back than was considered a TIM only overclockers would dare to use. Once we applied it, CPU temperatures dropped so much that we suspected that something is wrong with the CPU power or the thermal sensors.

We never looked back. The extra thermal headroom enabled increasing max power of the next generations of that industrial PC by 50% at the same form factor.

What about reliability, fried motherboards and liquid metal dry-out ?

Reliability is key for industrial PC, much more than in any consumer product. IPCs work 24/7 often at harsh environments where they are subject to extreme temperatures, shock and vibration, humidity, pollution, marine environment, dust and so on.

IPCs often run mission critical applications and are usually unattended.

Unreliable PCs are disqualified by customers, together with their manufacturer.

We had to run the IPC with liquid metal through rigorous tests, HAST, aging, certification tests and burn-in tests. On the way we acquired better understanding of liquid metal stability, long term behavior, interactions with other materials.

Our experience was very different from the experience many users share online. The IPCs never failed thermally and never had liquid metal spilling over boards and components. The IPCs did not require renewing the liquid metal throughout their lifetime. We made thousands of them, each with 5 year warranty.

Actually this page is written on such an IPC with liquid metal that I have been using as my fanless workstation for the last 5 years.

Why ALMAKIT was developed

Attractec was founded in 2021. We continued developing liquid metal IPCs. Liquid metal allows fanless IPCs to run at 10ºC – 15ºC higher ambient temperatures than competing fanless products with conventional TIM, while being at least 30% smaller.

An example for a modern fanless liquid metal IPC is SolidRun Bedrock which Attractec helped develop.

Production scaling challenge

For years we were training technicians personally on how to apply liquid metal using the conventional syringe and swab. It normally requires close guidance and inspection for several dozens of units until the technician acquires the skill to apply liquid metal reliably by this method, during which personal supoervision is required since poor liquid metal application in an IPC is not an option.

What happens when we need to manufacture thousands of liquid metal IPCs a month and train dozens of technicians in liquid metal application? The problem becomes unsustainable. The solution must come in the form of a better liquid metal application process – easy to learn and use, controlled, precise and with optimal performance results. Needless to say, if we could find such a process and tools, most effective would be to buy and use it. Unfortunately we could not find any – tier 1 vendors were using automated application with questionable results that were not only proprietary, but also too unreliable for IPCs, while the DIY community continued to consider liquid metal application a black art reserved for experts who seemed satisfied with the conventional syringe and swab method. We were in close relationships with some of the leading professional liquid metal vendors (and still are) but they could not offer a suitable solution or point out one. We realized that if we want a better method, we will have to develop it.

ALMAKIT Developed out of necessity

Attractec started R&D on “Attractec Liquid Metal Application Kit” – ALMAKIT – in 2021. Initially we intended to offer a disposable ready-to-use dispenser and applicator, but there is a gotcha – liquid metal is corrosive to aluminum and is therefore considered a hazardous material for air-freight which would have made the initial ALMAKIT distribution impractical.

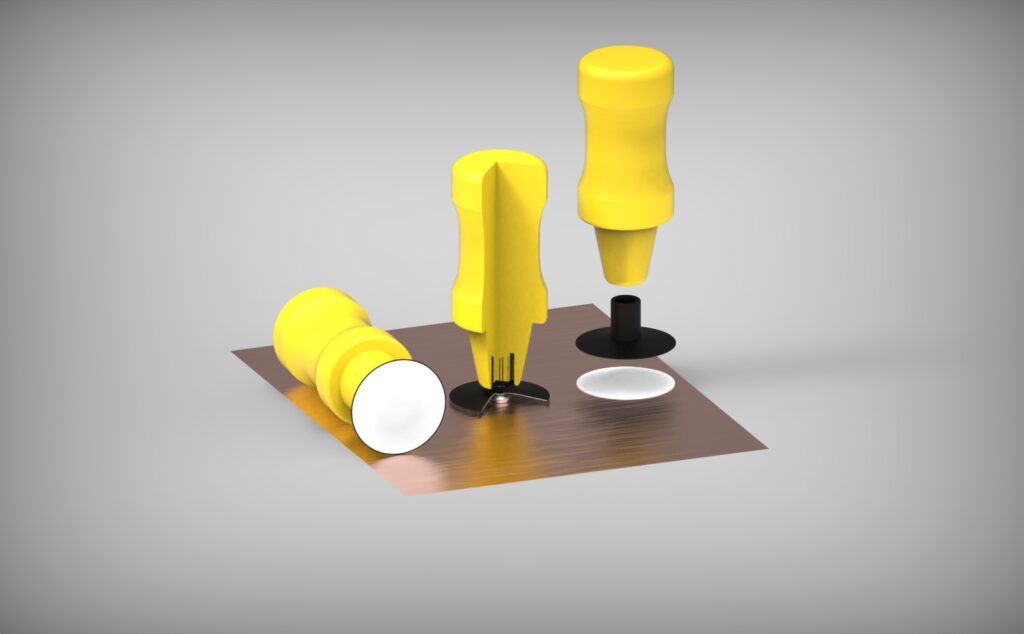

An old 2021 concept of ALMAKIT liquid metal applicator

(This method does not work)

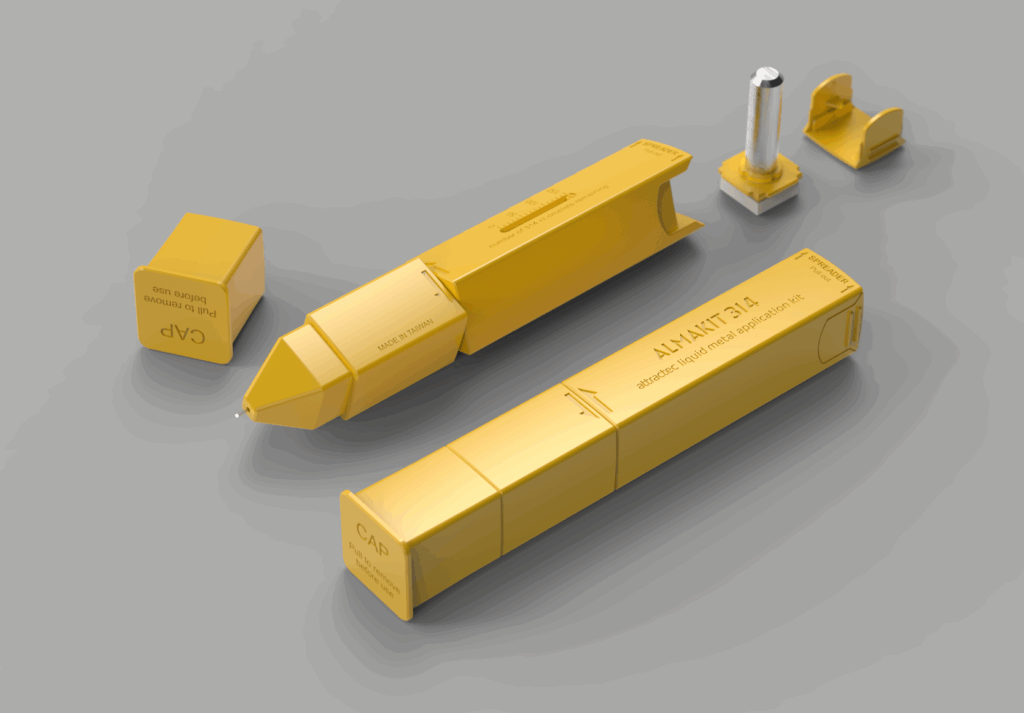

An old 2021 design of ALMAKIT disposable dispenser and applicator

(works, but falls under HAZMAT classification)

Nevertheless, the need for a better liquid metal application process remained.

We continued researching and refining the liquid metal application process and in 2025 we were satisfied enough with the process and tools and decided to take ALMAKIT to market as a reusable toolkit for liquid metal application, that is sold without the liquid metal itself.

The vision

We would like to make some observations:

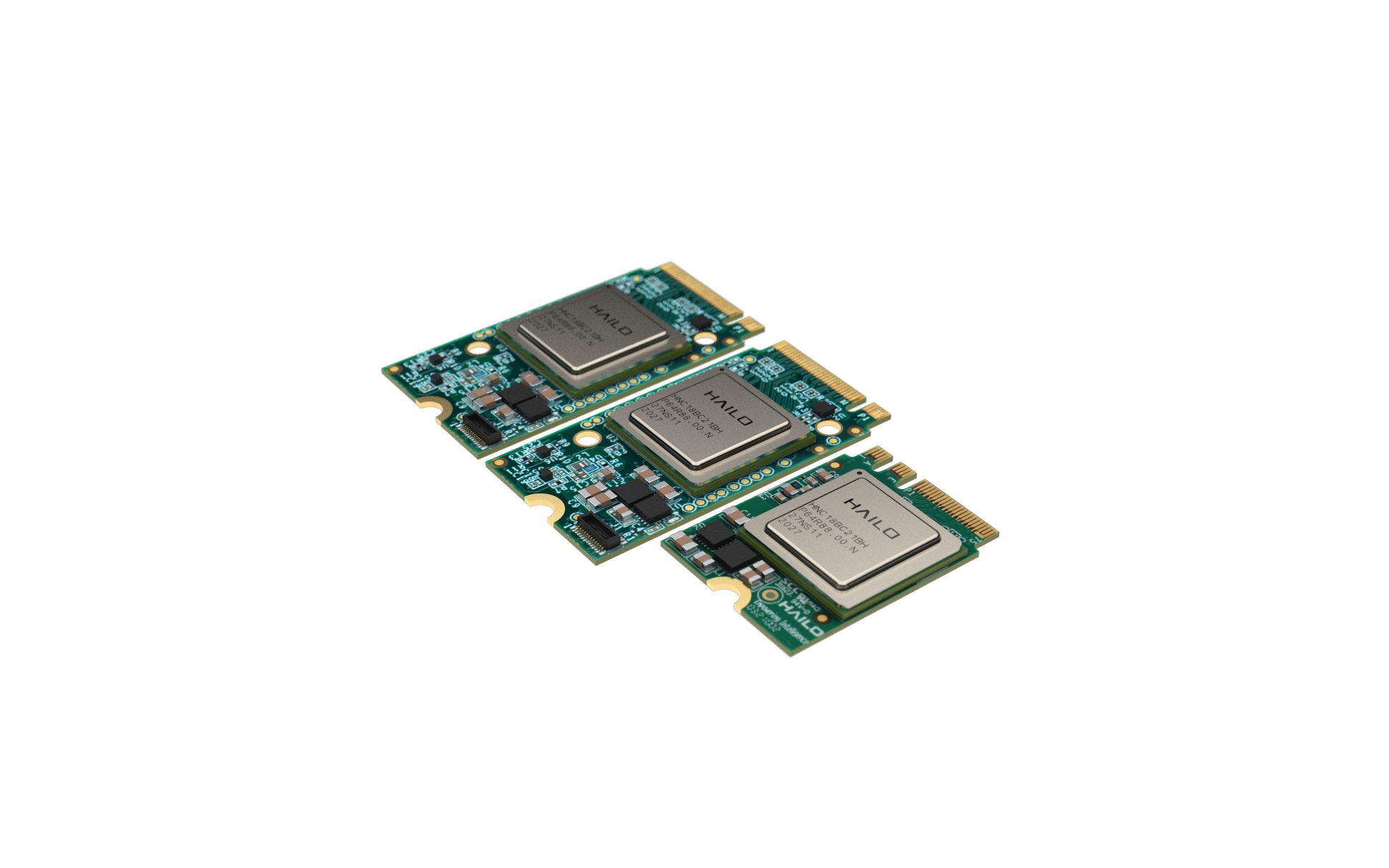

- The need for high performance TIM for chips will become more pressing with current industry trends

- Liquid metal will likely remain the highest-performance thermal interface material in the near future

- Despite superior performance, liquid metal adoption is limited since it is considered risky to electronics, unreliable and difficult to apply

We think that liquid metal application should be an easy, safe and precise process with optimal results in order to be adopted by more users and manufacturers.

ALMAKIT is our best effort in helping that to happen.

Thank you for your time,

Irad Stavi

CEO, Attractec

Nov 2025